Specification

Product Identification

- Product Code

- Core Dimensions

- Inductance Code

- Tolerance Code

General Specification

- Temp. rise: 20℃ max

- Ambient temp.: 60℃ max

- Operating temp.: -20℃~+80℃

- Terminal tensile strength: 1.0kg min

- Terminal bending strength: 0.3kg min

- Dielectric withstanding voltage: 250Vrms

- Rated current: base on temp rise

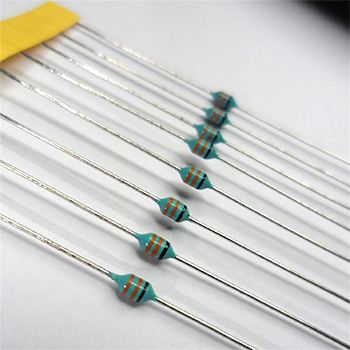

Materials

- Core: Ferrite DRWW

- Wire: Enamelled copper wire

- Lead: Tinned copper wire

- Coating: Epoxy resin

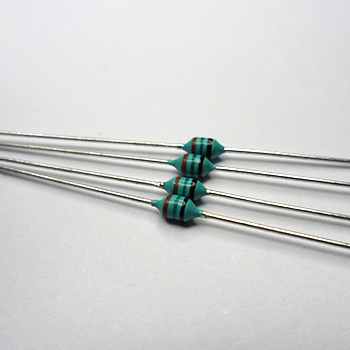

Part No. & Dimensions Line

| COLOR

| Nominal Inductance (H) |

| First Figure |

Second Figure |

Magnification/* |

Tolerance |

| BLACK (Bk) |

0 |

1 |

±20% |

| Brown (Bn) |

1 |

10 |

- |

| Red (R) |

2 |

100 |

- |

| Orange (O) |

3 |

1000 |

- |

| Yellow (Y) |

4 |

- |

- |

| Green (Gn) |

5 |

- |

- |

| Blue (Bu) |

6 |

- |

- |

| Violet (V) |

7 |

- |

- |

| Gray (Gy) |

8 |

- |

- |

| White (W) |

9 |

- |

- |

| Gold (Gd) |

- |

0.1 |

±5% |

| Silver (S) |

- |

0.01 |

±10% |

ex:

- If nominal inductance & tolerance is 22mH, ±10% respectively red+red+orange+silver should be marked;

- If nominal inductance & tolerance is 18uH, ±10% respectively brown + gray + black + silver should be marked;

- If nominal inductance & tolerance is 0.39uH, ±20 respectively orange + white + silver + black should be marked.

Q values for reference only

| Part Number

| Inductance

(μH) |

Test frequency

(MHz) |

Q

(min) |

S.R.F.

(MHz)min |

D. C. Resistance

(Ω)max |

IDC

(mA)max |

Color Code |

| 1st |

2nd |

3rd |

| AL0204-R10M |

0.10 |

25.2 |

50 |

250 |

0.030 |

700 |

Bn |

Bk |

S |

| AL0204-R12M |

0.12 |

25.2 |

55 |

230 |

0.035 |

600 |

Bn |

R |

S |

| AL0204-R15M |

0.15 |

25.2 |

55 |

200 |

0.040 |

620 |

Bn |

Gn |

S |

| AL0204-R18M |

0.18 |

25.2 |

55 |

180 |

0.045 |

600 |

Bn |

Gy |

S |

| AL0204-R22M |

0.22 |

25.2 |

55 |

160 |

0.050 |

400 |

R |

R |

S |

| AL0204-R27M |

0.27 |

25.2 |

50 |

150 |

0.065 |

380 |

R |

V |

S |

| AL0204-R33M |

0.33 |

25.2 |

50 |

150 |

0.075 |

370 |

O |

O |

S |

| AL0204-R39M |

0.39 |

25.2 |

50 |

150 |

0.080 |

350 |

O |

W |

S |

| AL0204-R47M |

0.47 |

25.2 |

60 |

150 |

0.085 |

330 |

Y |

V |

S |

| AL0204-R56M |

0.56 |

25.2 |

60 |

150 |

0.090 |

320 |

Gn |

Bu |

S |

| AL0204-R68M |

0.68 |

25.2 |

50 |

120 |

0.100 |

310 |

Bu |

Gy |

S |

| AL0204-R82M |

0.82 |

25.2 |

50 |

110 |

0.150 |

290 |

Gy |

R |

S |

| AL0204-1R0K |

1.0 |

25.2 |

50 |

110 |

0.220 |

270 |

Bn |

Bk |

Gd |

| AL0204-1R2K |

1.2 |

7.96 |

40 |

100 |

0.300 |

260 |

Bn |

R |

Gd |

| AL0204-1R5K |

1.5 |

7.96 |

40 |

80 |

0.350 |

250 |

Bn |

Gn |

Gd |

| AL0204-1R8K |

1.8 |

7.96 |

40 |

65 |

0.450 |

240 |

Bn |

Gy |

Gd |

| AL0204-2R2K |

2.2 |

7.96 |

40 |

55 |

0.550 |

230 |

R |

R |

Gd |

| AL0204-2R7K |

2.7 |

7.96 |

40 |

50 |

0.600 |

220 |

R |

V |

Gd |

| AL0204-3R3K |

3.3 |

7.96 |

40 |

42 |

0.650 |

210 |

O |

O |

Gd |

| AL0204-3R9K |

3.9 |

7.96 |

45 |

38 |

0.850 |

200 |

O |

W |

Gd |

| AL0204-4R7K |

4.7 |

7.96 |

45 |

34 |

1.00 |

190 |

Y |

V |

Gd |

| AL0204-5R6K |

5.6 |

7.96 |

45 |

32 |

1.15 |

180 |

Gn |

Bu |

Gd |

| AL0204-6R8K |

6.8 |

7.96 |

40 |

30 |

1.20 |

175 |

Bu |

Gy |

Gd |

| AL0204-8R2K |

8.2 |

7.96 |

40 |

26 |

1.25 |

165 |

Gy |

R |

Gd |

| AL0204-100K |

10.0 |

7.96 |

40 |

24 |

1.5 |

160 |

Bn |

Bk |

Bk |

| AL0204-120K |

12.0 |

2.52 |

40 |

22 |

2.2 |

150 |

Bn |

R |

Bk |

| AL0204-150K |

15.0 |

2.52 |

50 |

20 |

2.5 |

145 |

Bn |

Gn |

Bk |

| AL0204-180K |

18.0 |

2.52 |

50 |

18 |

2.8 |

140 |

Bn |

Gy |

Bk |

| AL0204-220K |

22.0 |

2.52 |

50 |

17 |

3.0 |

130 |

R |

R |

Bk |

| AL0204-270K |

27.0 |

2.52 |

55 |

14 |

3.5 |

80 |

R |

V |

Bk |

| AL0204-330K |

33.0 |

2.52 |

55 |

14 |

3.8 |

76 |

O |

O |

Bk |

| AL0204-390K |

39.0 |

2.52 |

50 |

13 |

4.2 |

74 |

O |

W |

Bk |

| AL0204-470K |

47.0 |

2.52 |

50 |

12 |

5.8 |

70 |

Y |

V |

Bk |

| AL0204-560K |

56.0 |

2.52 |

50 |

11 |

6.4 |

68 |

Gn |

Bu |

Bk |

| AL0204-680K |

68.0 |

2.52 |

50 |

10 |

7.2 |

64 |

Bu |

Gy |

Bk |

| AL0204-820K |

82.0 |

2.52 |

50 |

9.5 |

8.5 |

46 |

Gy |

R |

Bk |

| AL0204-101K |

100.0 |

0.796 |

50 |

9.0 |

11 |

44 |

Bn |

Bk |

Bk |

| AL0204-121K |

120.0 |

0.796 |

40 |

6.5 |

13 |

42 |

Bn |

R |

Bn |

| AL0204-151K |

150.0 |

0.796 |

40 |

6.0 |

16 |

39 |

Bn |

Gn |

Bn |

| AL0204-181K |

180.0 |

0.796 |

40 |

5.2 |

18 |

37 |

Bn |

Gy |

Bn |

| AL0204-221K |

220.0 |

0.796 |

40 |

4.5 |

20 |

35 |

R |

R |

Bn |

| AL0204-271K |

270.0 |

0.796 |

30 |

3.5 |

29 |

28 |

R |

V |

Bn |

| AL0204-331K |

330.0 |

0.796 |

30 |

3.0 |

30 |

26 |

O |

O |

Bn |

| AL0204-391K |

390.0 |

0.796 |

30 |

2.7 |

32 |

25 |

O |

W |

Bn |

| AL0204-471K |

470.0 |

0.796 |

30 |

2.6 |

35 |

24 |

Y |

V |

Bn |

| AL0204-561K |

560.0 |

0.796 |

30 |

2.5 |

40 |

23 |

Gn |

Bu |

Bn |

| AL0204-681K |

680.0 |

0.796 |

30 |

2.2 |

42 |

22 |

Bu |

Gy |

Bn |

| AL0204-821K |

820.0 |

0.796 |

30 |

2.1 |

46 |

21 |

Gy |

R |

Bn |

| AL0204-102K |

1000.0 |

0.796 |

30 |

2.0 |

52 |

20 |

Bn |

Bk |

R |

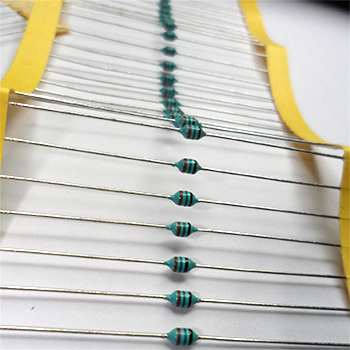

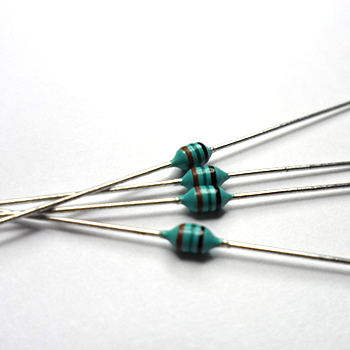

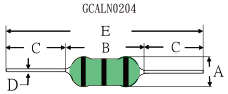

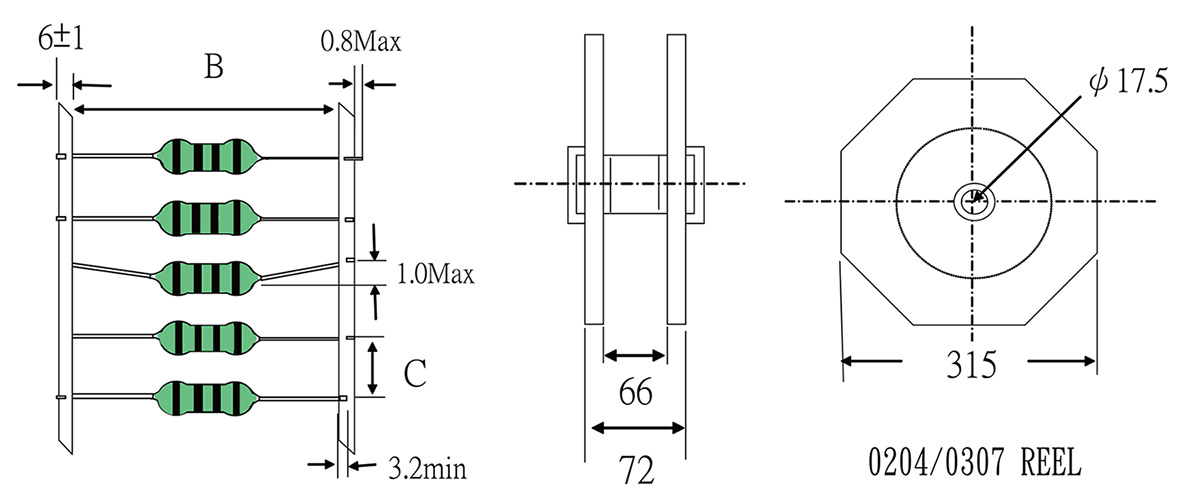

Mechanical Drawing

| TYPE

| GCALN0204 |

| ΦA +0 |

2.8 mm |

| B +0 |

4.4 mm |

| C ±3.0 |

29.5 mm |

| ΦD ±0.05 |

0.5 mm |

| E ±2.0 |

62.0 mm |

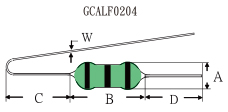

| TYPE

| GCALF0204 |

| ΦA +0 |

2.8 mm |

| B +0 |

4.4 mm |

| C MAX |

6.0 mm |

| D min |

3.6 mm |

| ΦW ±0.05 |

0.5 mm |

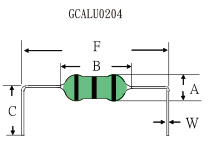

| TYPE

| GCALU0204 |

| ΦA +0 |

2.8 mm |

| B +0 |

4.4 mm |

| C ±1.0 |

6.0 mm |

| F ±1.0 |

10.0 mm |

| ΦW ±0.05 |

0.5 mm |

Dimensions of Reel & Packing Unit

| Sym.

| 0204 |

| B |

52.0 ±1.0 mm |

| C |

5.0 ±0.5 mm |

Packing Unit for Reel

| Item

| 0204 |

| Quantity/ Reel |

5,000 PCS |

| Quantity/ Carton |

25,000 PCS |

| GW/ CTN (Approx.) |

9.0 Kgm |

| Carton Size (mm) |

330 * 330 * 460 |

Applications

- Electronics products

- Communications equpments

- Computer Devices

- TV, VCR

- Battery charger

OEM/ODM

G-CHEN will also produce devices outside these specifications to meet specific customer requirements, please contact our sales for more information.