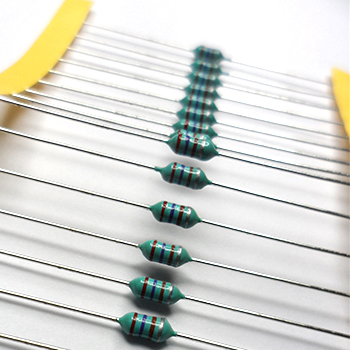

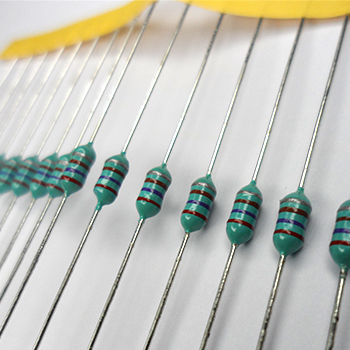

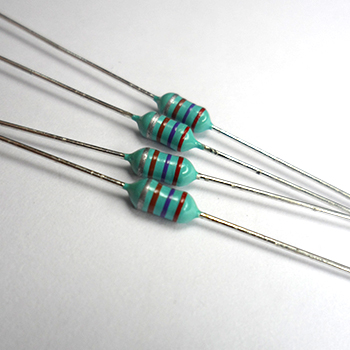

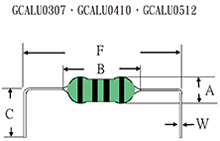

GCAL0307 Series

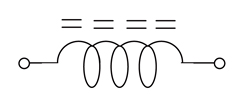

Axial Inductor

Features

In addition to Axial Inductor, we also provide Wide Band Choke, T-Core Iron Choke, and UU&UT Filter Inductor.

- Design to be compact, small and light-weight

- Wide range of inductance

- Contribute to be high Q and self-resonant frequencies

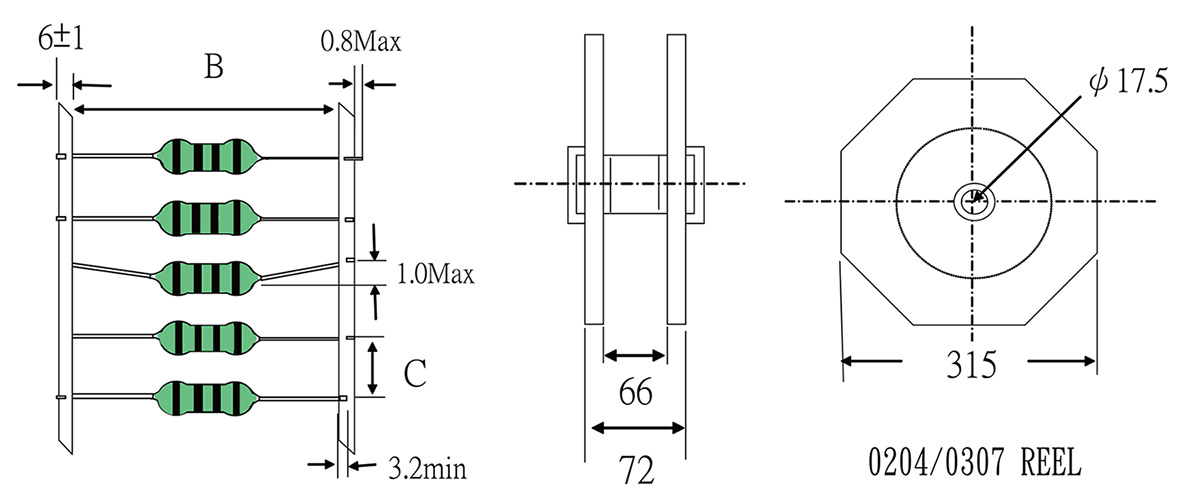

- Tapping type that is convenient for automatic insertion

- Coating epoxy resin that ensure the humidity resistance to be long life

- Low Cost

- Design to be compact, small and light-weight

- Wide range of inductance

- Contribute to be high Q and self-resonant frequencies

- Tapping type that is convenient for automatic insertion

- Coating epoxy resin that ensure the humidity resistance to be long life

- Low Cost