GSCD TYPE

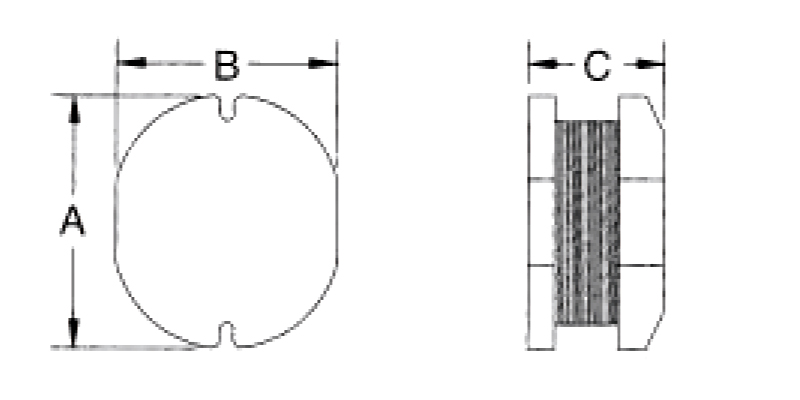

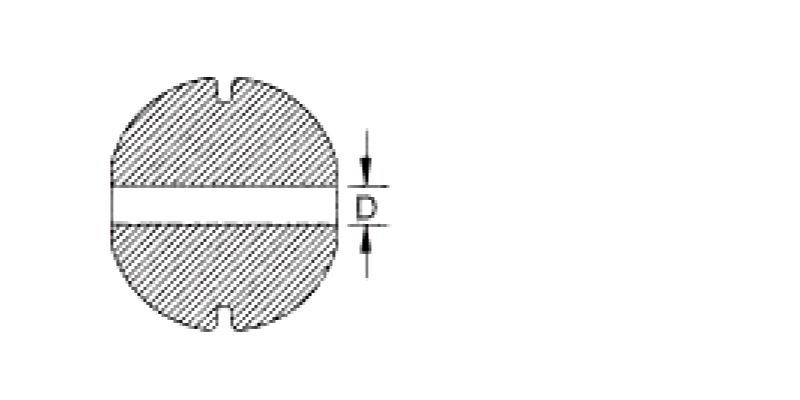

SMD POWER INDUCTOR

Features

We provide various Inductors, such as Air Coil Inductor, Coil Inductor, Spring Coils Inductor, DIP Power Inductor, Leaded Power Inductor and Power Inductor, all with superior quality.

- Excellent solder ability and high heat resistance.

- Excellent terminal strength constructio

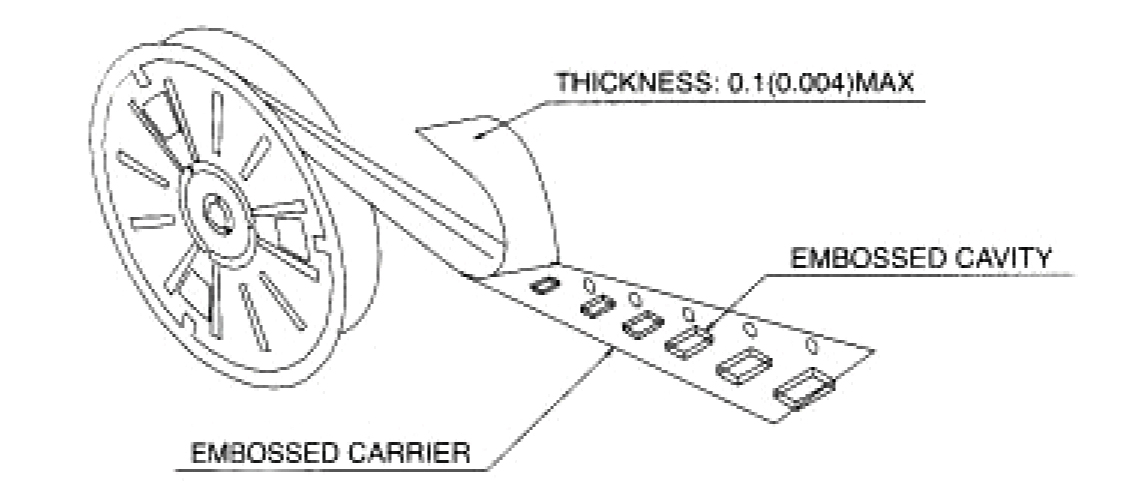

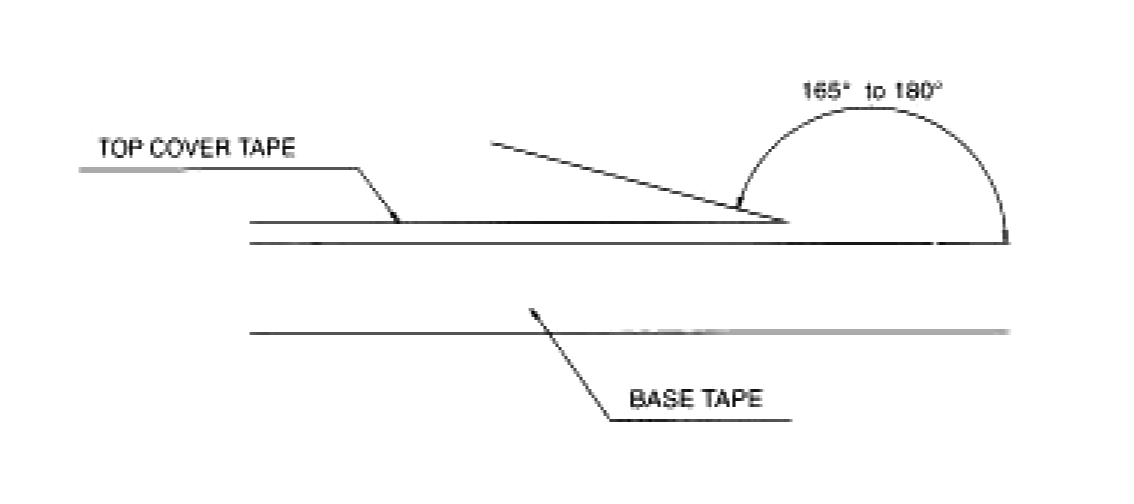

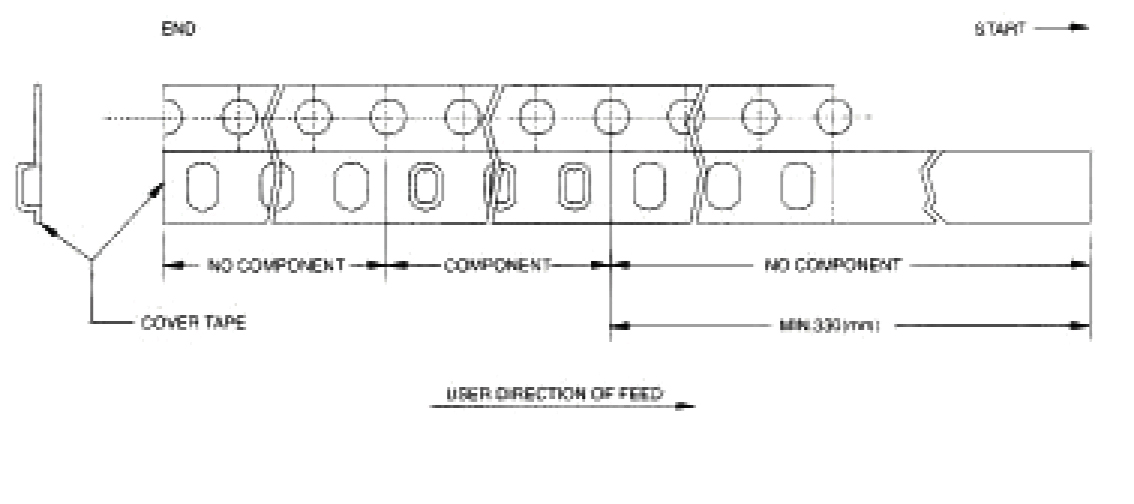

- Packed in embossed carrier tape and can be use by automatic mounting machine.

- Low cost feature.

- Excellent solder ability and high heat resistance.

- Excellent terminal strength constructio

- Packed in embossed carrier tape and can be use by automatic mounting machine.

- Low cost feature.